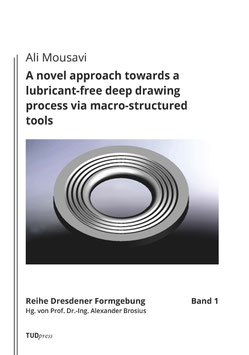

A novel approach towards a lubricant-free deep drawing process via macro-structured tools

von Ali Mousavi

Reihe Dresdener Formgebung hrsg. von Alexander Brosius; Bd. 1

TUDpress 2020. Kartoniert, ca. 21,1 x 15 cm, 117S.

In today’s industry, the sustainable use of raw materials and the development of new green technology in mass production, with the aim of saving resources, energy and production costs, is a significant challenge. Deep drawing as a widely used industrial sheet metal forming process for the production of automotive parts belongs to one of the most energy-efficient production techniques. However, one disadvantage of deep drawing regarding the realisation of green technology is the use of lubricants in this process. Therefore, a novel approach for modifying the conventional deep drawing process to achieve a lubricant-free deep drawing process is introduced within this thesis.

In order to decrease the amount of frictional force for a given friction coefficient, the integral of the contact pressure over the contact area has to be reduced. To achieve that, the flange area of the tool is macro-structured, which has only line contacts. To avoid the wrinkling, the geometrical moment of inertia of the sheet should be increased by the alternating bending mechanism of the material in the flange area through immersing the blankholder slightly into the drawing die.

ISBN: 978-3-95908-197-9

24,80 €

inkl. MwSt, zzgl. Versandkosten

Versandkostenfrei in folgende Länder: Mehr anzeigen Weniger anzeigen

- verfügbar

- 3 - 5 Tage Lieferzeit1